There is a system behind each refinery or manufacturing facility that circulates fluids throughout the day, every day with no pause. Industrial pumps don’t get noticed until there’s an issue, but they are essential in modern day industry. Choosing the right screw pump & pump parts manufacturer or working with trusted Industrial Centrifugal Pump Manufacturers often makes the difference between smooth operations and costly downtime.

These pumps are designed for areas where reliability is paramount. They push water, chemicals or slurries along with other fluids through complex systems. Unlike smaller commercial pumps, industrial pumps are made for continuous use, harsh materials, and extreme conditions that do not allow for compromises.

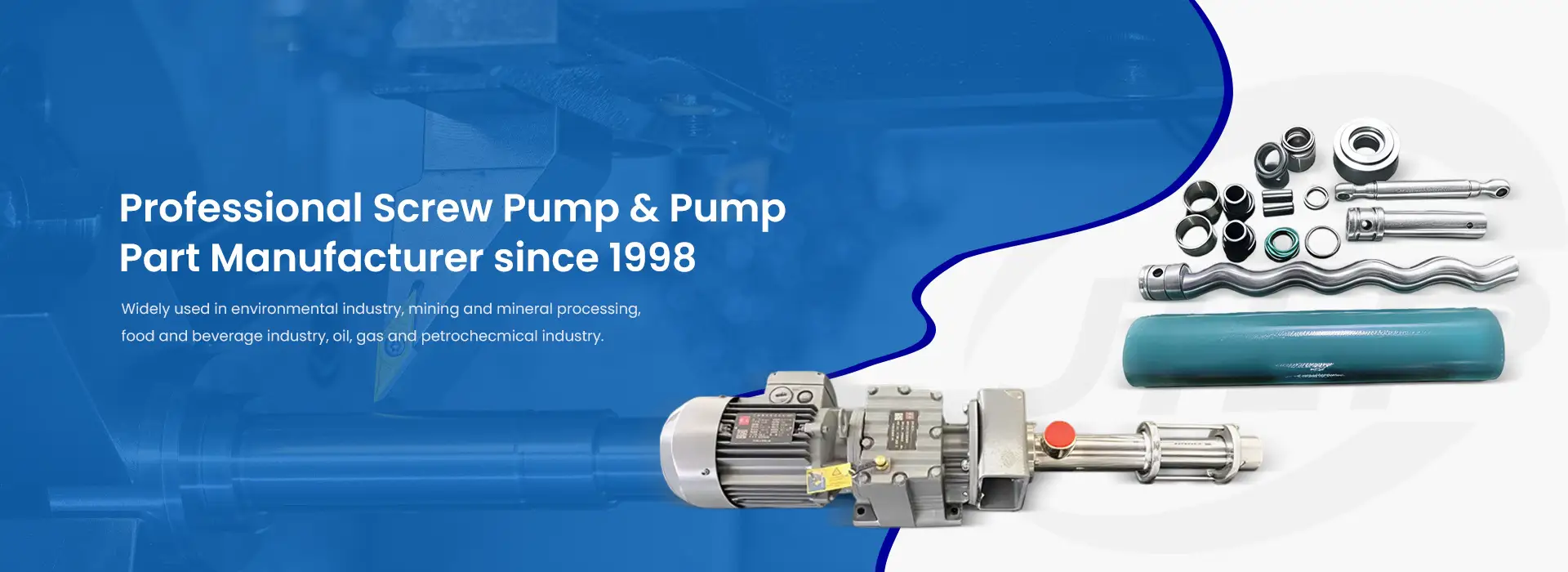

Image credit: lepuseal.com

Understanding Centrifugal Pumps and Applications for Screw Pump Applications

The centrifugal pump is among of the most commonly used industrial pump types. The simple design of centrifugal pumps and their consistent flow, and their energy efficiency makes them the perfect choice to move large quantities of medium to low viscosity fluids. This is the reason that the majority of manufacturers of Industrial Centrifugal Pumps give a top priority to the improvement of impeller geometries, casing material, and the performance of their motors. These improvements decrease energy consumption and provide consistent output for long operating times.

Screw pumps play a completely distinct, but equally important function. They’re best suited for applications where consistency of fluid is crucial, especially when working with materials that are thicker. Sludges, oils, and viscous chemicals require smooth, pulse-free movements, which screw pumps provide with precision. Specialized screw pumps and parts manufacturers understand how internal tolerances as well as rotor designs influence performance and longevity under pressure.

Together, they provide a variety of industrial needs ranging from simple water transfers to sophisticated chemical handling and process handling.

The importance of pump parts is greater than you believe

The reliability of a pump is determined by the components inside. Mechanical seals, shafts, casings and bearings are exposed to constant pressure, friction and wear. Minor component failures in time can result in vibrations, leaks, or system shut downs. This is the reason having access to high-quality replacement parts is as crucial as the pump itself.

Many industrial operators prefer working with suppliers who provide complete pumps instead of purchasing parts from a variety of suppliers. The availability of quality, compatible parts can cut down on equipment downtime and prolongs its life. It also simplifies maintenance planning and helps keep systems operating within design limits.

Lepu Seal is a reliable option for industrial buyers due to the reliability of this strategy. By offering both full pumping systems as well as an extensive assortment of spare parts, Lepu Seal supports long-term operation stability across various industries.

Created for industries that simply can’t afford to pay for downtime.

Industrial pumps are employed in refineries, chemical plants, factories, wastewater systems, and even energy-related operations. In the event of failure, it is not just frustrating but it could also cause a disruption to entire production lines. This is why testing procedures along with manufacturing standards and quality controls are vital.

Trustworthy manufacturers test pumps under real operating conditions prior to shipping. Pressure checks, material inspections and performance tests help ensure every unit meets strict expectations. This focus on detail allows industrial users to operate confidently knowing that their equipment is made to last.

As industries continue to scale and develop, the need for sturdy pumps and reliable components continues to grow. Utilizing experienced Industrial Centrifugal Pump Manufacturers and reliable pump parts suppliers will ensure that the pumps are durable, efficient and up to the demands of continuous operation. In the end, reliability isn’t just an option, it’s the underlying principle of industrial success.